our products

VERMEER PROCESS: DEDICATED TO SOLUTIONS

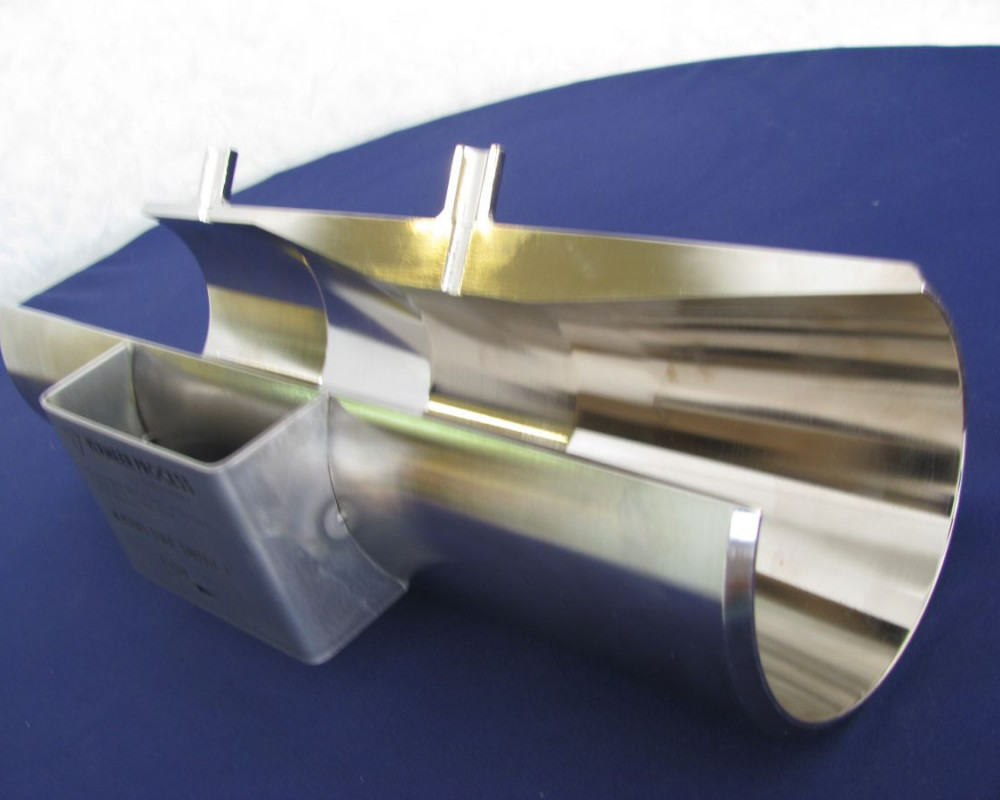

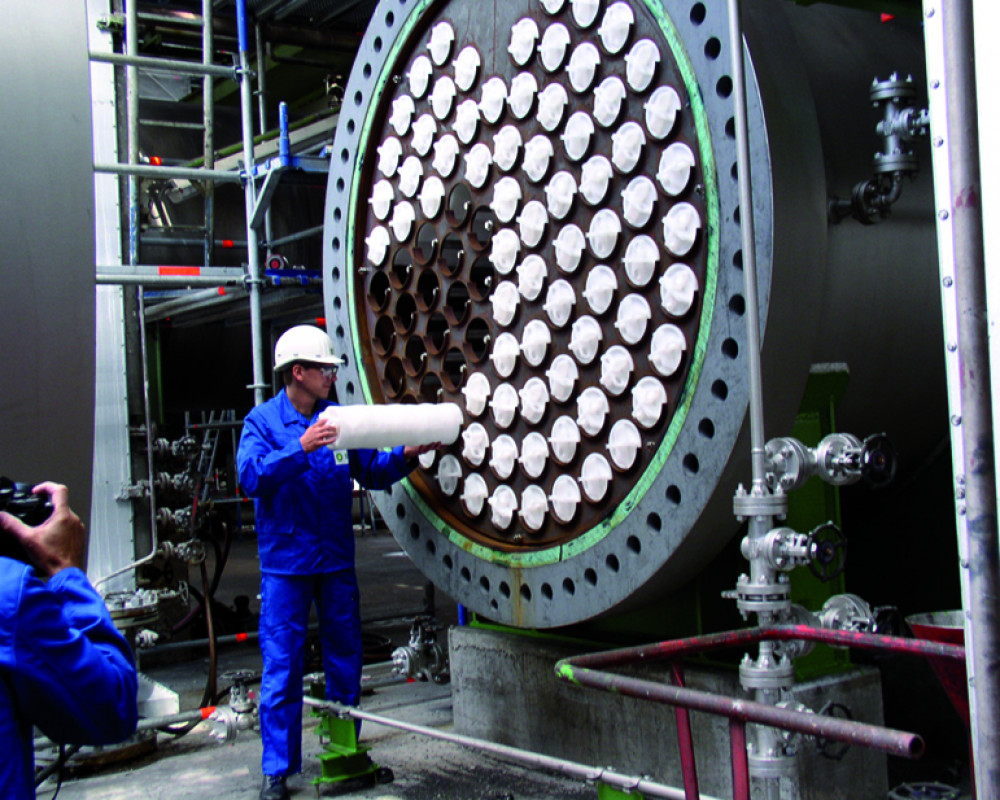

The range of products that Vermeer Process Technology designs and fabricates, comprehends not only filters, strainers, self-cleaning filters and flow equipment, but also specially developed one-offs. Keywords for all of our products are filter efficiency, extended lifetime, price-quality ratio and decreased maintaining costs by reducing shut down time. Vermeer Process Technology has experience in working with almost any (exotic) material you can think of.