Vermeer Denver. The reliable source for valves and associated products

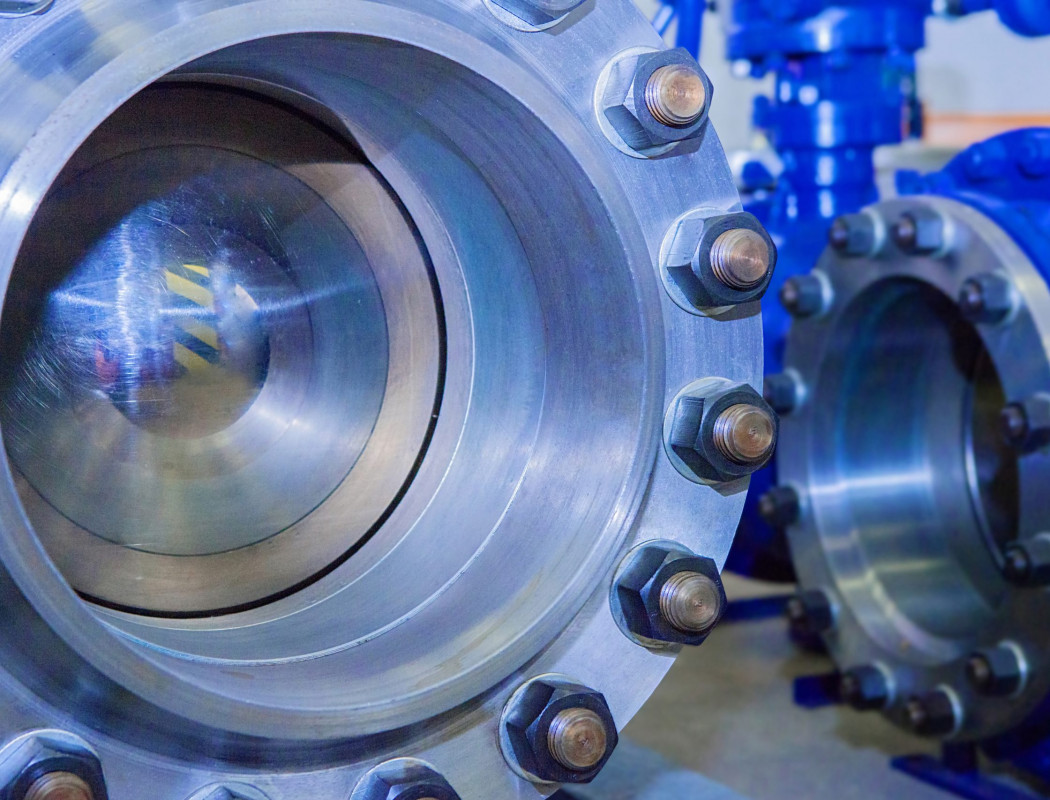

Optimizing and Regulating the flow

Denver International was established in 1988 and joined the VE Group in 2016 as Vermeer Denver International BV. A new team of professional valve experts as well as commercial sales force strengthened our position on the industrial world market. Our goal is to supply the correct valve for the specified application in a timely manner. Our engineering department contributes to the development and design of special valves for the most demanding of applications. We supply our valves globally.

Design standards:

API, ASME, ISO, BS, DIN, GOST

Materials of Construction:

Carbon Steels, Stainless Steels, Duplex Steels, Titanium, Nickel Alloys.

Pressures Classes:

150# up to API 10.000, PN 20 up to PN 420.

VDI, with more than 40 years of experience in the supply of industrial valves supplies highly-engineered, one-off valves, as well as complete valve packages for hydrocarbon processing, chemical industry, energy and cryogenic installations. VDI is the reliable source for all your valves and valve products. Based on the appropriate design standards and the client’s requirements, VDI will supply the correct valve or valves; designed, manufactured, tested and certified as specified.

Temperature range:

– 196 C. up to+ 550 C.

Certification:

Valves supplied by VDI are produced under ISO 9001-2008 and in accordance with PED/EC Module H. As a standard, all valves are certificated acc. EN 10204.3.1 material and test certificates, higher certification levels on request. Valves can be supplied with all NDE as may be required: Hydrotest, High Pressure Gas Tests Emission Tests, M.P.E., L.P.E. , Hardness Tests, P.M.I., Charpy V-Tests, Ferrite Tests and more.