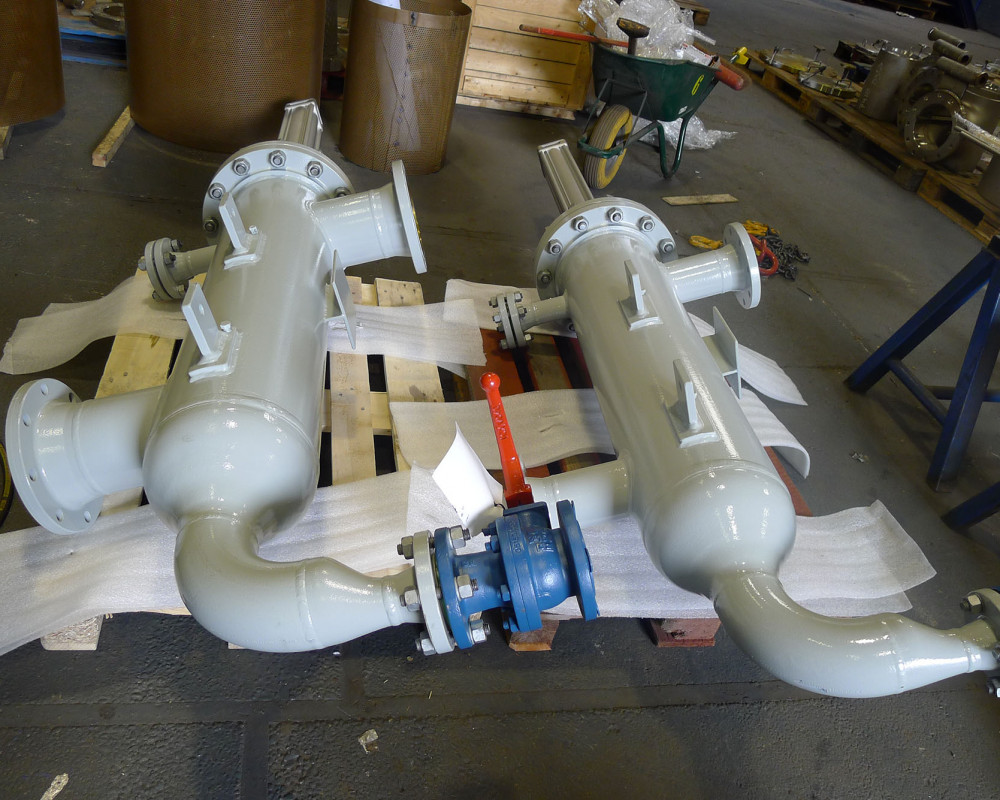

Cast strainers

Cast strainers are used in various industrial environments. There size may vary from 1” up to 60”. Typical applications are water intake, fire fighting, process fluids, condensate water, cooling water, pre-filtration of water treatment systems. Cast strainers can handle any type of fluid in any viscosity. Vermeer Process Technology cast strainers are common in the petro-chemical industry, in oil & gas industries and in various other industrial markets where standard strainers are sufficient. For special use, Vermeer Process Technology can design and produce custom made cast strainers.

REMOVE SOLIDS WITHOUT STOPPING THE FLOW

Instead of trapping solids in a basket which must then be removed for frequent clean-outs, the strainer removes solids from the fluid flow without stopping the flow or disassembling the strainer. A simple turn of the hand wheel (or actuation of the screen motor in automatic units) rotates the screen against a scraper bar. Debris moves to a sump area where it is removed by periodic flushing.

MANUAL OR AUTOMATIC OPERATION

The strainers are available in manual or automatic models. A full array of controls is available for remote, automated operation of automatic models. Manual models can be upgraded to automatic operation in the field without disruption of the fluid handling system.

OUR WELDERS ARE CLASSIFIED FOR ALL TYPES OF MATERIAL

- All stainless steel types, such as AISI 316, 316L, 316Ti, 321 etc.

- Duplex and Superduplex, 254 SMO

- Nickel alloys like hastelloy ® and monel ®

- Titanium

- Carbon steel

- Cast steel, such as A216 WCB, A234 WPB and CF8M (s.s.)

- Cast iron ASTM 278

- Alubronze ASTM B148 (seawater resistant)