ThermEx Products

TOP QUALITY HEATING SYSTEMS

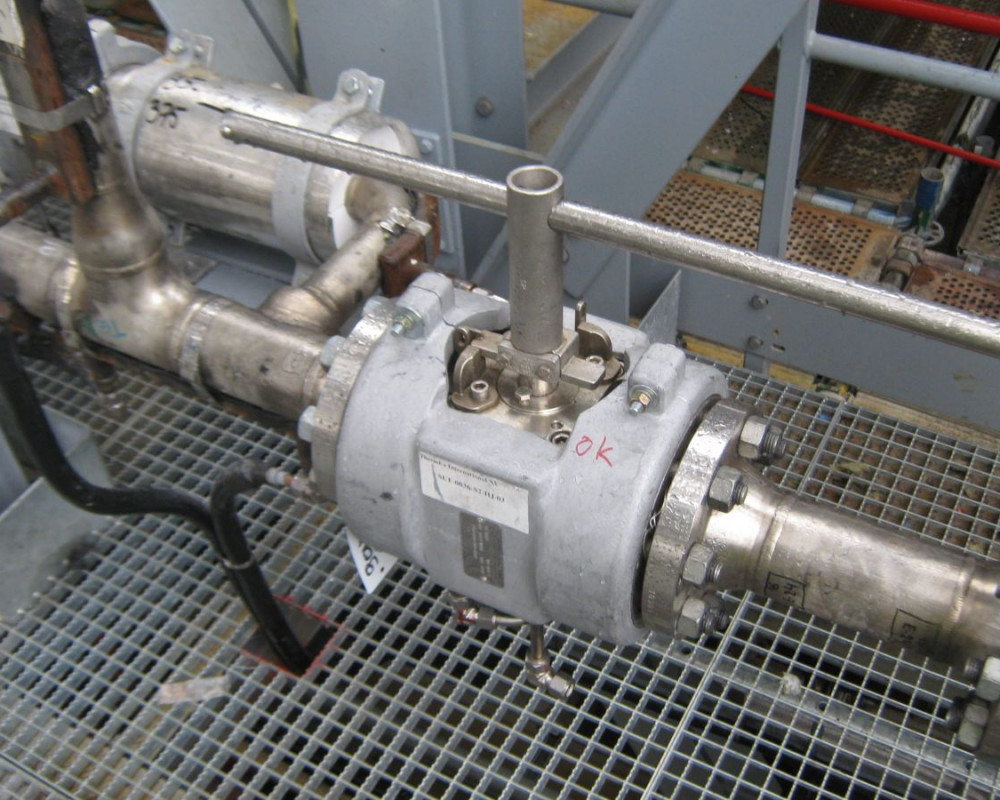

The ThermEx Clamp-On Heating jackets are used for components as the alternative to welded-on or cast-on heating jackets, suitable for valves, pumps, meters and all in line equipmen…

view product

The ThermEx Thermal Maintenance System is used as external heating system on storage tanks, in cases where contamination from internal coil leaks cannot be tolerated and/or the wal…

view product

The ThermEx Thermal Maintenance System is used as external heating system on drums, in cases where contamination from internal coil leaks cannot be tolerated and/or the wall temper…

view product

The ThermEx Thermal Maintenance System is used as external heating system on vessels, in cases where cross-contamination from welded-on half pipe heating systems or internal serpen…

view product

The ThermEx Thermal Maintenance System is used in several piping applications to keep the process flowing, to prevent cross-contamination of the heating medium and he process mediu…

view product