GLOBE VALVES

A globe valve is a type of control valve that is used to modulate flow. Though a globe-shaped body is a typical characteristic of globe valves, they can come in a variety of shapes and sizes, depending on their design. A thorough understanding of how a globe valve works can help determine the right solution for each application.

What is a globe valve?

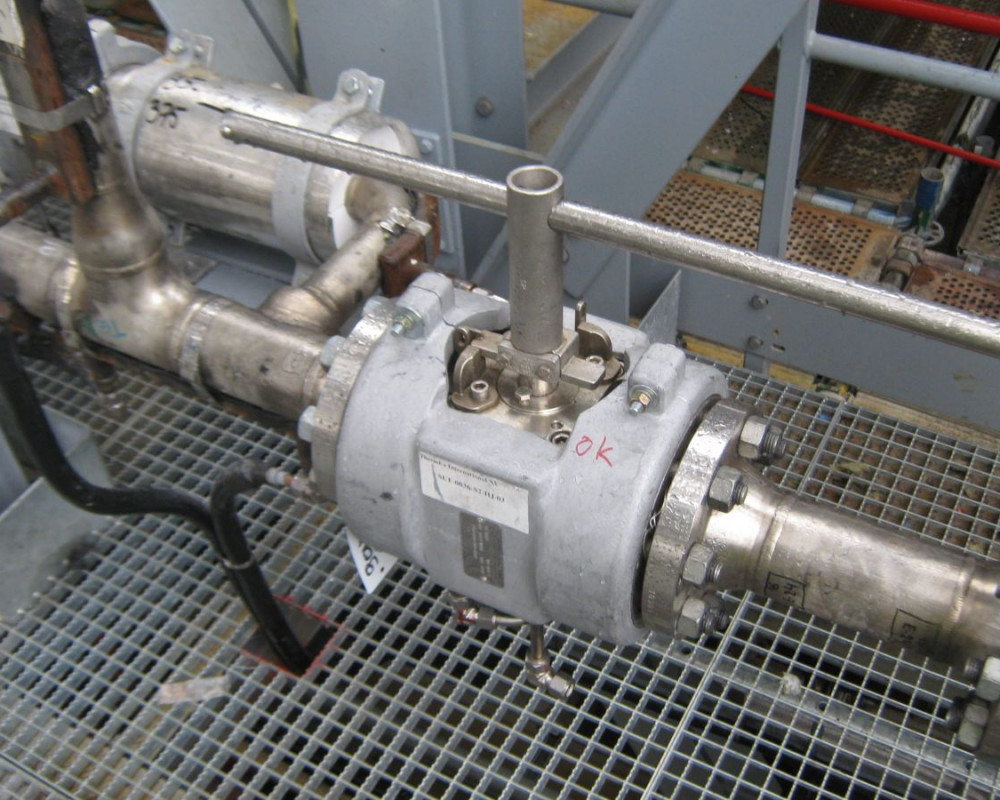

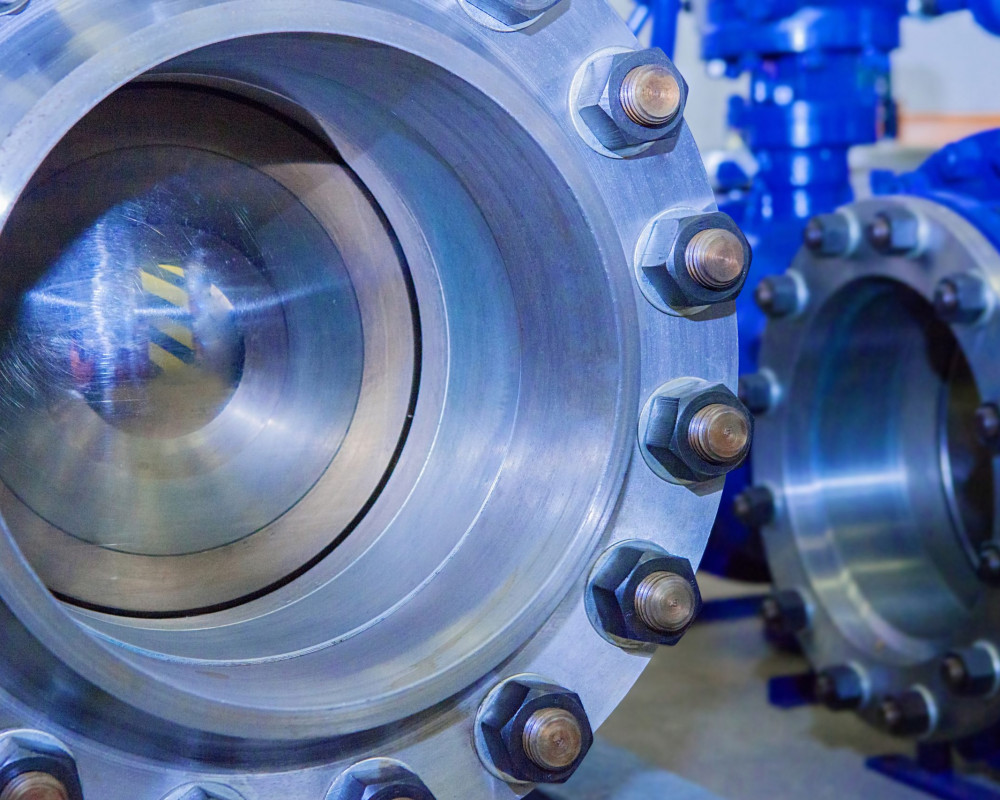

Initially characterized by their spherically shaped valve bodies, globe valves use a moveable plug or disc to control flow between the two separate chambers in the valve body. The disc moves in a linear direction as its actuator (handwheel or actuator) such as in figure 1) rotates the stem lifting or lowering the plug or disc. This either allows flow, modulates the flow, or stops the flow through the orifice.

How a globe valve works

The exterior structure of a globe valve includes a valve body, handwheel, and bonnet. A threaded valve stem or screw connects to the handwheel and penetrates into the bonnet. On the interior end of the valve stem is a disc or plug, which can be a variety of shapes, depending on the application.