BUTTERFLY VALVES

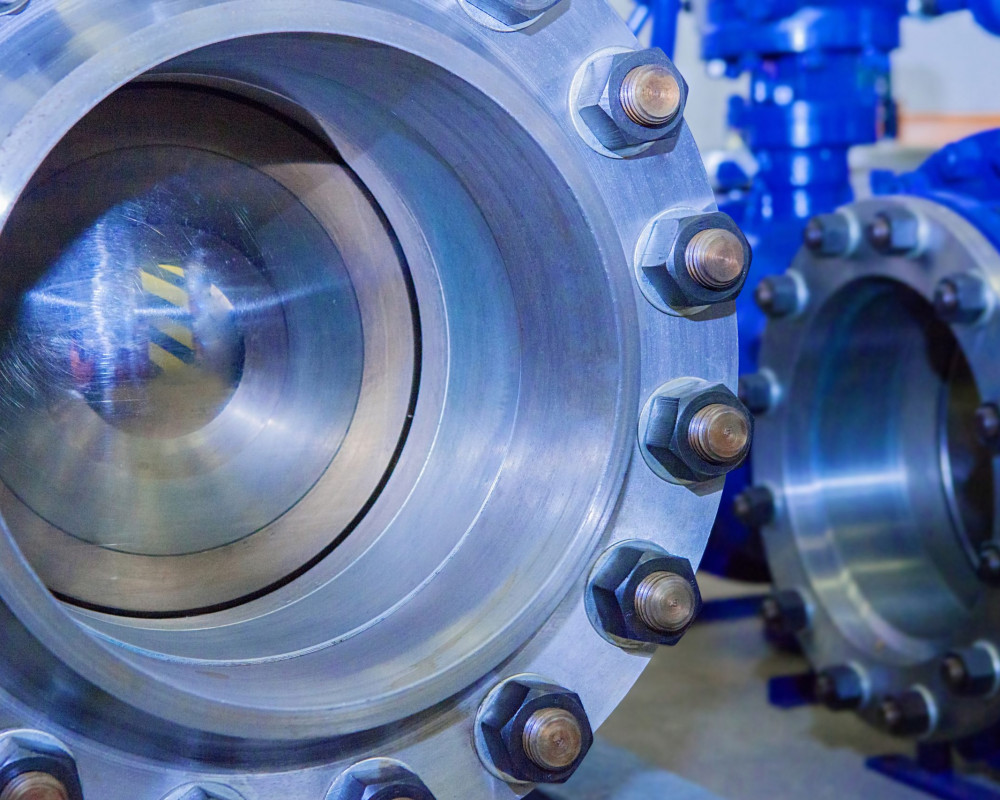

Butterfly valves are a family of quarter-turn valves and work very similar to ball valves. The ‘butterfly’ is a disk connected to a rod. When the valve opens, the disk rotates to allow fluid to pass through. It closes when the rod rotates the disc by a quarter turn to a position perpendicular to the flow direction. Butterfly valves are popular for on-off or modulating services due to their lightweight, small installation footprint, lower costs, quick operation, and availability in huge sizes. These valves can be operated by handles, gears, or automatic actuators.

Types of butterfly valves

Butterfly valves come in diverse designs, each serving specific applications and pressure ranges. Butterfly valves can be categorized based on their disc closure design, connection design, and actuation method.

Disc closure design

Butterfly valves can be concentric or eccentric depending on the location of the stem in relation to the disc and the seat surface angle on which the disc closes.

Concentric

The most basic type of butterfly valve design is a centric or concentric butterfly valve. This means that the stem passes through the centerline of the disc, which is in the center of the pipe bore, and the seat is the inside diameter periphery of the valve body (Figure 4 on the left). This zero-offset valve design is also called resilient-seated because it relies on the flexibility of the seat rubber to efficiently seal the flow when closed. In this type of valve, the disc first comes into contact with the seat at around 85° during a 90° rotation. Concentric butterfly valves are commonly used for low-pressure ranges.