NEW KAFO CNC DRILLING MACHINE

We are proud to announce that we will add another state of the art drilling machine to our production facility. The VE GROUP is unique, constantly finding ways to automate parts of the production process. This enables us to keep reducing turn around time of manufacturing schedule. With our state of the art machine park, the VE Group is also fully equipped for the re tubing and repair of heat exchangers. You will find a full overview of our machines here.

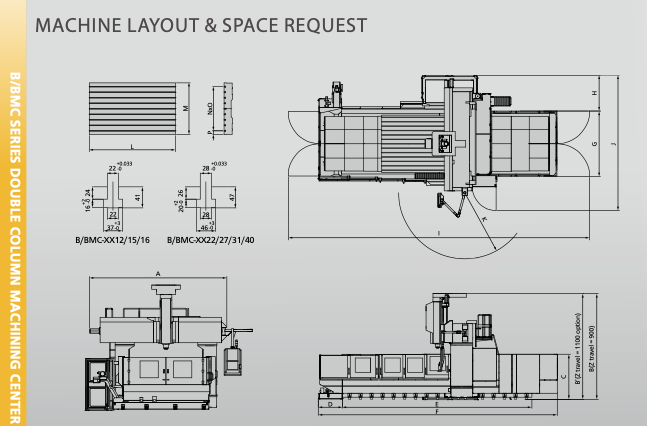

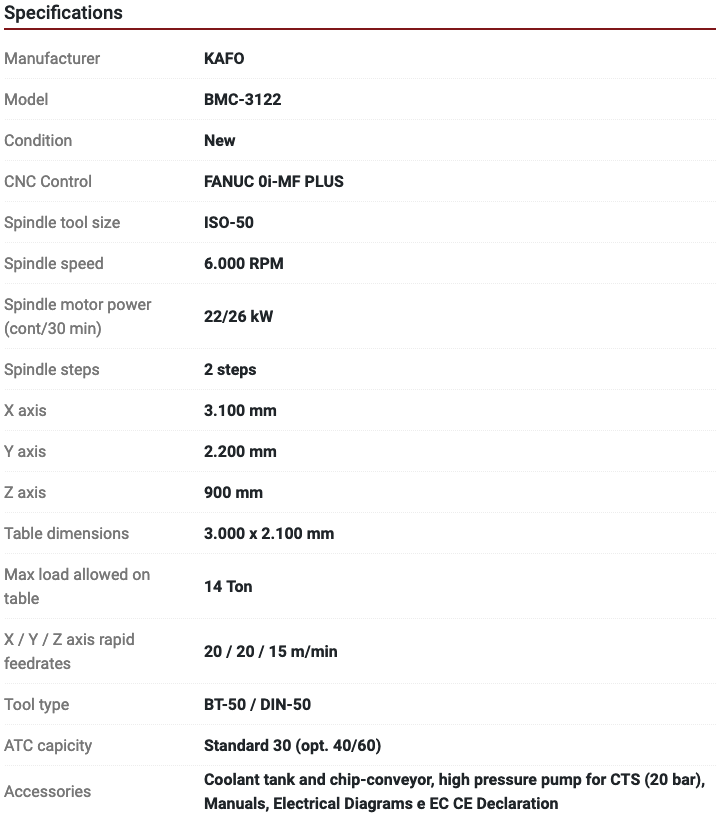

KAFO BMC 3122

Other news

VE GROUP FEBRUARY UPDATE

2026: A Year of Growth and Innovation in Oil & Gas Equipment Manufacturing The oil & gas sector is gaining fresh momentum in 2026, and equipment manufacturing is at the cen

VERMEER & GREENDUSTRY

Read the newspaper article here World-famous in our own backyard, Vermeer Eemhaven International in Rotterdam is proud to be part of the shift, turning traditionally gray business