Submerged Arc Welding

functionality

Automated submerged arc welding, more commonly abbreviated to SAW, or Sub Arc Welding is a wire-fed weld process that’s either fully or partially automated. It’s mostly used for weld processes on thicker steels including carbon steels, stainless steels and some nickel alloys. SAW is ideal for welding materials between a half-inch to 5-inches thick, however, by making adjustments to the travel speed and heat input, SAW can be used for metals of just 3/16th of an inch without burn-through. The term itself (Submerged Arc) refers to the arc being submerged in a granular flux. There’s no visible/open arc, so there’s no fumes and no weld spatter.

efficiency

Higher deposition rates are the main advantage as it improves productivity Due to the semi or fully automated process, there’s improved ergonomics for operators with minimal manipulation of workpieces required. Full control of the weld parameters enables high quality welds consistently Flux recovery reduces wastage Deep weld penetration on thick steels can be done, sometimes in a single pass Welds on thinner metals can be done at high speed and without burn-through No spatter and no fumes provides a safer working environment.

other projects

CNC DRILLING KAFO BMC 3211

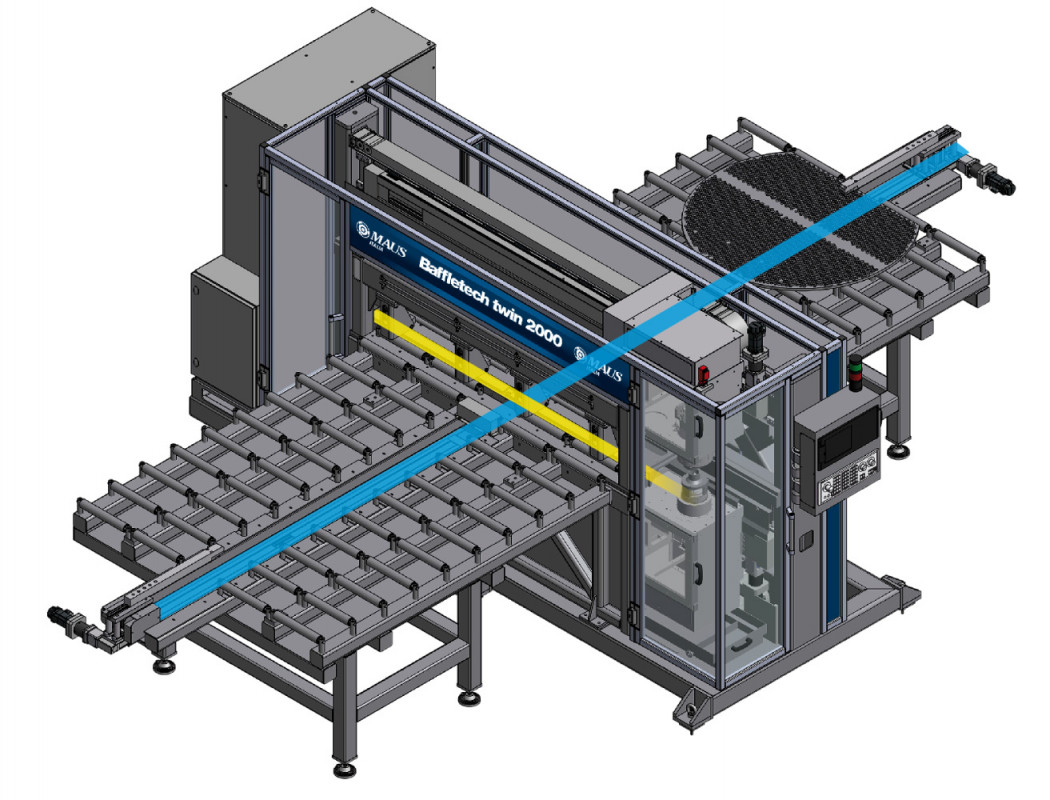

view equipment