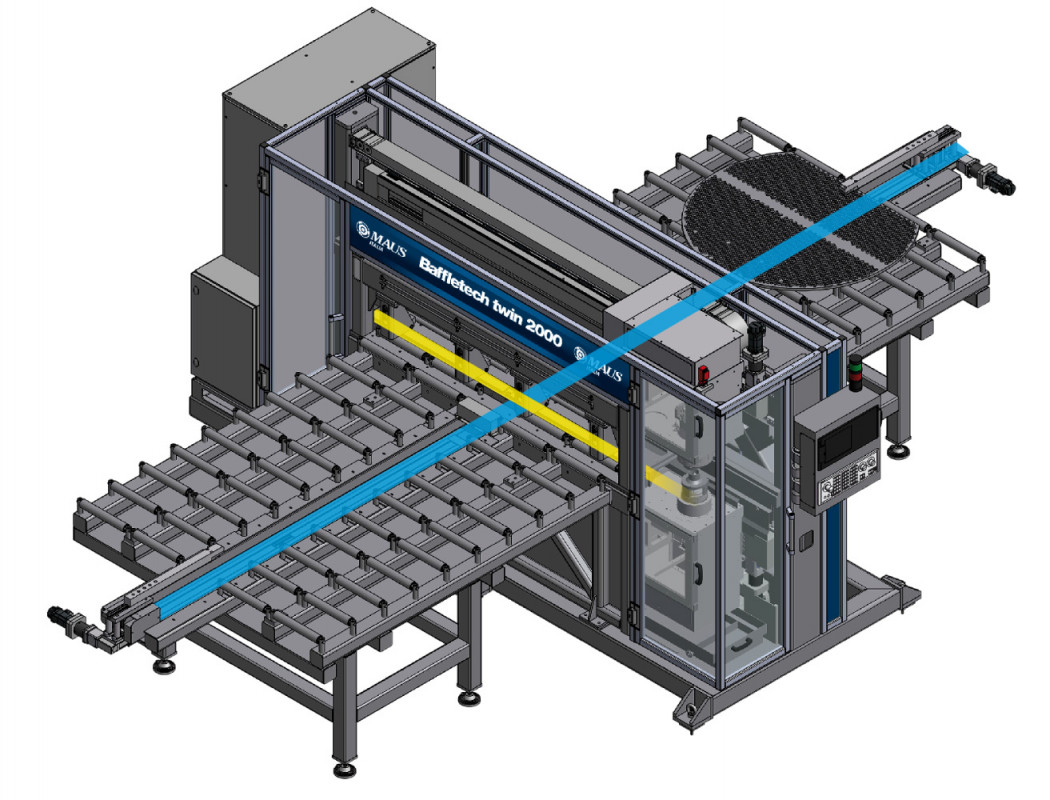

GALBIATI state of the art double spindle drilling

functionality

The Galbiati drilling machine for deep drilling shell and tube heat exchanger plates (ASME, TEMA, and PED codes)used in chemical, petrochemical and nuclear industries. 2 spindles, with BTA (STS) and Gundrilling systems. STRENGTHS High positioning accuracy and repeatability, highly bore straightness, concentricity precision Automatic drilling, advanced control systems monitor the cutting fluid flow and pressure, axial movement, thrust, and power of each individual spindle Use of the most modern Siemens CNC Control Systems for monitoring the functions of motors, digital drives and spindles. Pre-programmed CNC. Recording of drill data and cycles Design using FEM to guarantee greatest structural stiffness and to dampen the vibrations caused by the cutting process The machine and equipment are modular and can be customized Milling Unit (optional) for finishing the plates

efficiency

Our Galbiati brings a speed increase on the drilling process of around 40% compared to conventional CNC drilling machines.