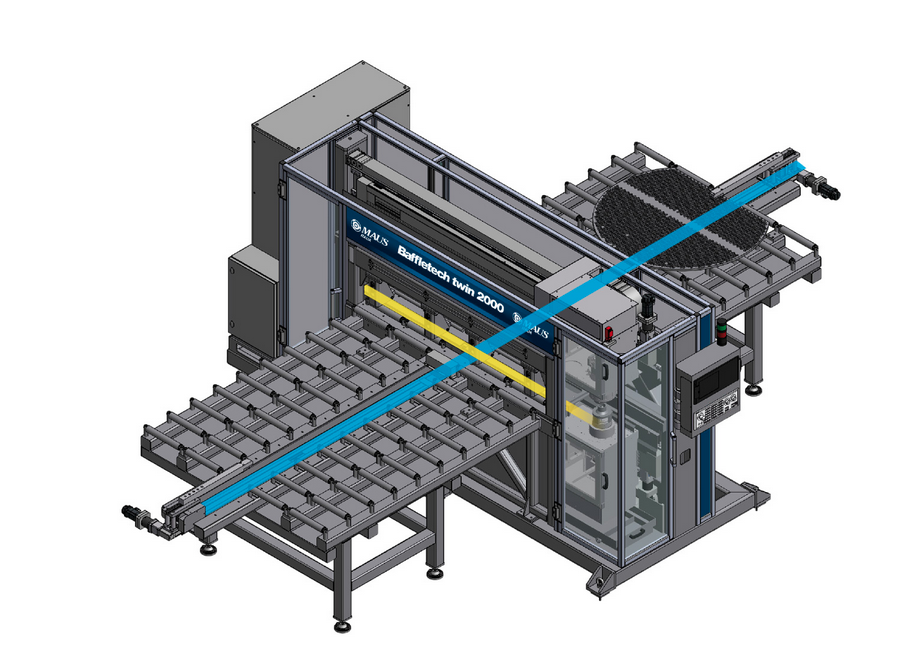

Baffletech twin 2000 @ work

We are proud to announce that last week our newest investment was commissioned in our production facility. Yet another great collaboration between Maus Italia and the VE Group!

In 2023 the VE Group and MAUS signed an agreement for the design and manufacturing of the NEW BaffleTech twin 2000. Yet another step towards a completely automated production train for the construction of heat exchanger tube bundles. The process of de-burring in the industry is done by hand hole by hole with a conventional drill. From now on at the VE Group the MAUS baffle tech will do a 1.000 holes per hour, flawlessly.

The Baffletech twin 2000 allows the simultaneous flare of the holes on both sides of the baffle in a single pass without the need for additional operations thanks to two opposing heads which are equipped with self-centring tools.

With this revolutionary new solution coming from Maus we are able automate yet another process in the manufacturing of heat exchangers, shortening our lead time and ensuring flawless quality for our customers. The baffletech was added to our machine shop and commissioned in June 2024.

Want to know more about how this equipment can be of added value to the lead time of your project? Contact us via info@vermeereemhaven.nl

Other news

VE GROUP FEBRUARY UPDATE

2026: A Year of Growth and Innovation in Oil & Gas Equipment Manufacturing The oil & gas sector is gaining fresh momentum in 2026, and equipment manufacturing is at the cen

VERMEER & GREENDUSTRY

Read the newspaper article here World-famous in our own backyard, Vermeer Eemhaven International in Rotterdam is proud to be part of the shift, turning traditionally gray business